Operations Excellence Consulting

Consistent, safe, reliable operations start with a well-defined operations program. RMG’s operations excellence offering is a comprehensive review of the site’s operations processes and procedures.

Safe and reliable operations result from the consistent execution of a well-defined operations program. RMG’s operations excellence consulting services drive simple, clear, and consistent processes and procedures that reduce errors in communication and action. Reducing errors and instilling disciplined operational practices lead directly to lower risks to safety and reliability.

We understand that a comprehensive operations strategy must be designed to accommodate a balance of standardization across all units with procedures designed to drive cost-effective decisions at the unit level. Site- or company-specific processes and procedures are developed using in-house resources. Clear accountabilities for the oversight and execution of the processes are established. In-depth training and one-on-one coaching are conducted to drive the adoption of improved procedures. Crews experience quick benefits from improved communications, coordination, and consistent operating practices, and the entire site benefits from operations that are done right – every time.

Key Outcomes of Process Excellence Implementation

- Drives Team Concept – Stable Platform

- Improved Operations Work Management

- Instills Use of both Asset and Administrative Operational Procedures

- Drives Operator Ownership and Reliability Centered Operations

- Empowers Condition Based Monitoring

- Sets Operating Limits and Expectations

- Differentiates between Emergency / Upset Conditions

- Drives troubleshooting / Problem Identification

- Defines Shutdown Situations to avoid escalation to high-risk situation

- Drives Reliability Centered Maintenance

- Enforces all Elements of Site Support Operations

- Enhances Use of Personnel Assets

- Creates Mindset Change – Flawless Operations

- Drives Formal and Informal Training

Benefits from Operations Excellence Consulting:

- Reduce human errors to increase plant availability, lower equipment risk, and improve lost opportunity by:

- Ensuring accurate, complete information and data exchange in Operations

- Development of a process and procedure-based culture

- Establish effective management and improvement of operational practices

- Set up long-term management and sustainment of operational practices

- Limit the impact of experience loss due to turnover

- Improves overall Asset Management

- Increases Asset Availability

- Reduces Unplanned Capacity Loss

- Increases Mean Time Between Failure (MTBF)

- Improves On-Test Results – Product Compliance

- Improves Energy Intensity Index (EII)

- Improves Personnel / Equipment / Environmental Safety

- Enables World Class Performance

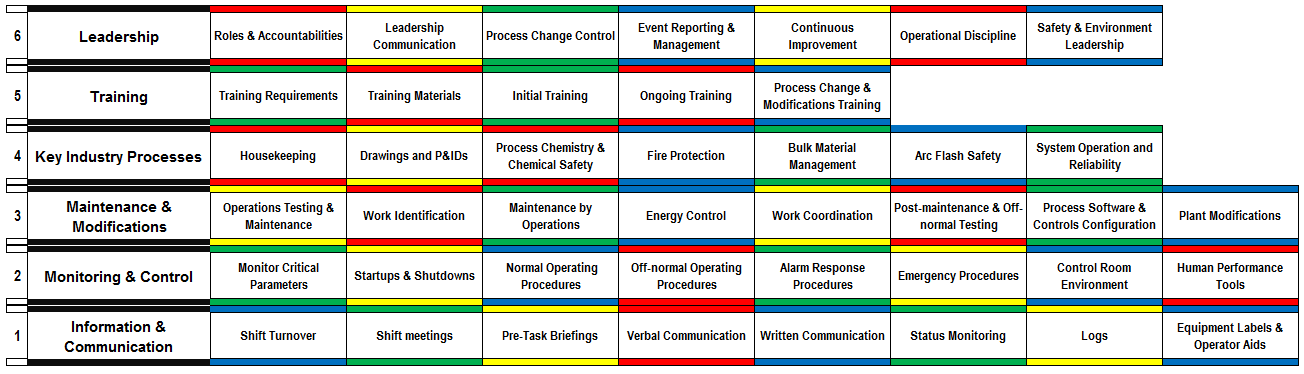

Operations Excellence Grid