Maintenance Management Consulting

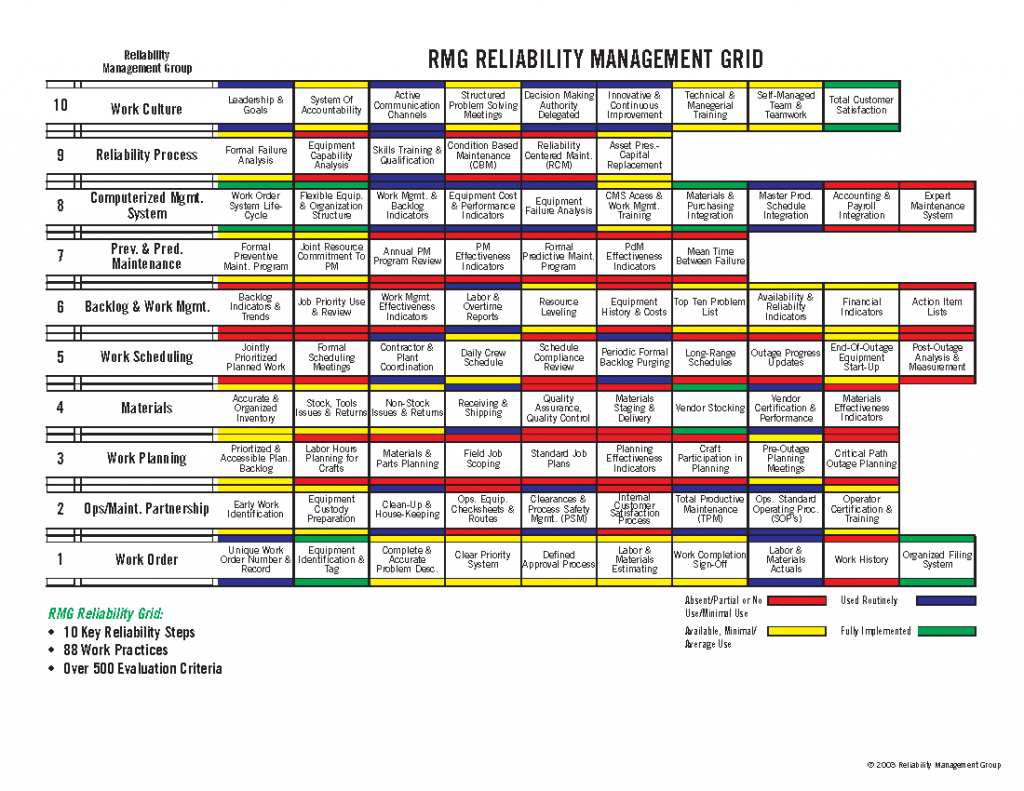

Our corporate philosophy centers on assisting our clients to achieve “Lowest Cost Reliability.” We understand that a comprehensive maintenance strategy must be designed to accommodate a balance of standardization across all units with procedures designed to drive cost-effective decisions at the unit level. We have leveraged our learnings and experiences over 30 years to continuously improve our Assessment and Implementation Methodologies. Continuous renewal of our methodology and best practices criteria ensures that our findings and recommendations are aligned with current industry best practices and sound change management principles.

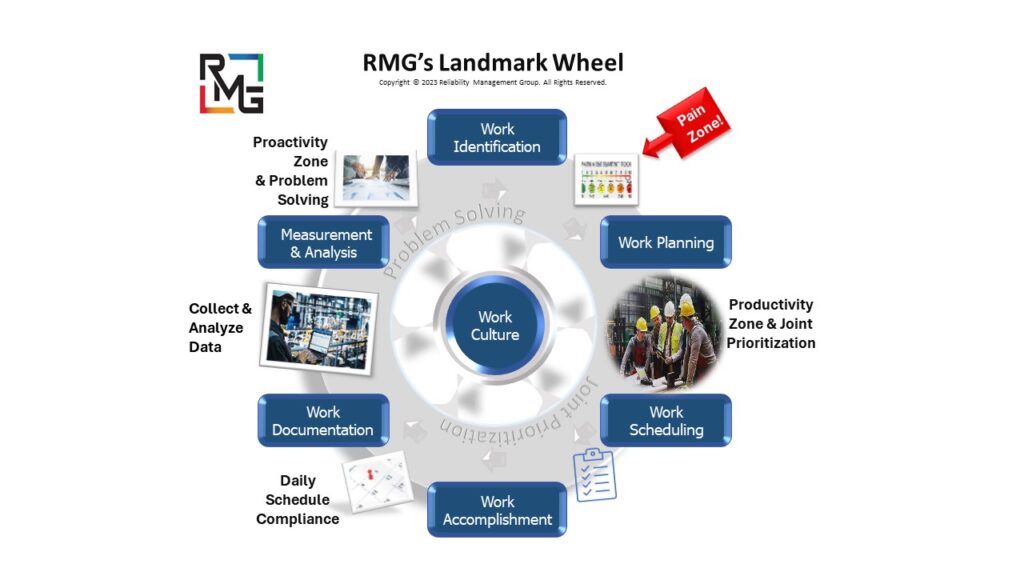

RMG Landmarks Wheel

RMG has extensive maintenance management services. Work management is a continuous process made up of six simple steps that RMG calls the “wheel”. Work must be identified, planned, scheduled and accomplished. Then the work must be documented so that data is available for analysis and measurement.

The analysis then loops back into work identification in the form of ongoing work like Preventive Maintenance (PM), or new work like capital projects. RMG has identified landmarks on the wheel that help us understand how the process really works and where the opportunities are, all while being surrounded by an organization’s culture. RMG utilizes the Landmarks wheel in conjunction with the Fundamentals wheel to explain the work management journey.

This review illustrates how to avoid the “Pain Zone” by focusing on the twin skills of planning and scheduling as the primary source of productivity in the work management process. Joint Prioritization engages operations, maintenance and engineering to jointly decide the order in which jobs will be done and work accomplished.

These activities enable forward-looking programs that help identify work early and move the organization away from a reactionary state and into proactivity! If you do the steps in the work management process well you can achieve lower cost reliability, but you can only achieve lowest cost reliability by aligning process and culture.

Identification

- Quality work request

- Equipment hierarchy & tagging

- Critical equipment list

- Operator responsibilities & procedures

- CMMS functionality

Planning

- Formal planning procedures

- Field job scoping

- Quality job package

- Standard job plans

- Parts/Materials assurance

- Clean, organized backlog

- CMMS functionality

Scheduling

- Worksite readiness

- Crew preparation & supervision

- Customer satisfaction

- Job closure

Accomplishment

- Resource coordination

- Long range scheduling

- Daily scheduling

- Ops/Maintenance commitment

- Parts staging & delivery

Documentation

- Key business indicators

- Work process indicators

- Equipment reliability indicators

- Problem-solving

- Proactive maintenance

- CMMS output

Analysis & Measurement

- Labor & materials actuals

- Work history

- Updated prints & drawings

- CMMS input