Industrial Asset Optimization Services

In today’s dynamic business landscape, proper asset management is crucial for organizations seeking to make informed decisions at the right time. By harmonizing the collective expertise of individuals, streamlined processes, and cutting-edge technologies, a well-defined strategy paves the way for achieving sustainable success.

Today’s businesses grapple with multiple challenges, including outdated infrastructure, a technology revolution, a retiring workforce, and increasing regulatory scrutiny. The primary objective of industrial asset optimization and management is to optimize equipment usage, maximize returns on asset investments, and minimize risks, exposure, and downtime. Additionally, it aims to enhance overall value and profitability.

A comprehensive asset management plan encompasses various facets, including design, inspection, maintenance, operational excellence, capital replacement, process optimization, and efficient asset data management. This balanced approach is designed to extend the lifecycle of equipment and infrastructure, ensuring long-term viability and success.

If your organization is facing these challenges, our asset management solutions can help you achieve your goals effectively.

RMG’s experts have deep industry knowledge in refining, mining, utilities, and manufacturing providing Asset Management solutions clients need to minimize their risk while maximizing their profits.

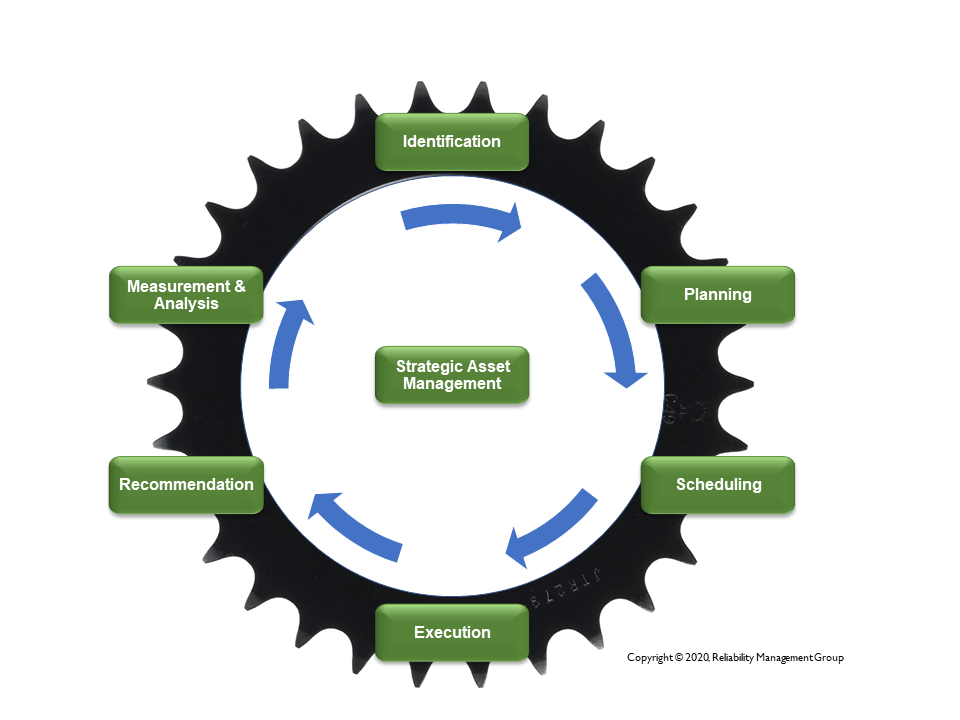

Identification

- Regulatory/Statory

- Asset Operational & Production

- Department Roles & Responsibilities

- Asset Register & Data Management

- Budget Plans & Constraints

- Organizational Performance

Planning

- Asset Strategy Plans

- Asset Audit Results

- Life-cycle Planning

- Budget / Capital Investment

- Emergency / Contingency

- Outsourcing / Contractor

- Decommission / Disposal

- Plans Review / updates

- Training Planning

Scheduling

- Improvement Initiative

- Assignments

- Audit Schedules

- Outage / Project Scheduling

- Production / Services Scheduling

- Training Schedules

- Outsource / Contractor Scheduling

- Analysis Activities

Execution

- Work Schedules:

- Maintenance

- Operations

- Engineering / Projects

- Supply Chain

- Progress Tracking & Updates

- Management of Change

- Information Management

- Asset Monitoring

- Financial Monitoring

- Metrics / Reporting

Recommendations

- Asset Performance Data & Condition

- Financial Data Integration

- Asset / Work Histories

- Asset Cost / Life Cycle

- Incident Documents

- Asset Register Updates

- Formal Change Procedure (Standards, Procurement, Equipment, SOP, etc.)

- Ops / Maint. / Engineering Work Processes

- Work Requirements / Procedures

- Contracts

- Inventory

- Skill Requirements

- Main Plans

- Ops Procedures

Analysis & Measurement

- Improvement Tracking / Value Analysis / Directives

- Asset Performance & Conditions Analysis

- Risk Analysis

- Reliability Analysis (FMEA, Critically, etc. )

- Incident Investigation / Directives

- Workforce Competency / Skills

- Asset Management Audits

- Asset Optimization