Background and Situation:

- Maintenance activities are driven by regulatory requirements and reaction to failures

- Underutilization of CMMS system (DataStream)

- Informal work process used to operate and prioritize work

- Inconsistent asset strategy because of multiple acquisitions

- Multiple cultures and inconsistent work process

- Inconsistent documentation of compliance work

Achievements:

- Developed, documented, & implemented a consistent maintenance work process across multiple legacy companies

- Configured CMMS system to align with industry best practices

- Developed and implemented consistent scheduling process

- Trained users’ company-wide on work management philosophy and expectations

- Trained users on proper usage of DataStream

- Implemented use of KPI’s to consistently drive behavior and performance

- Defined and implemented work prioritization methodology

- All compliance work captured and reported in CMMS system.

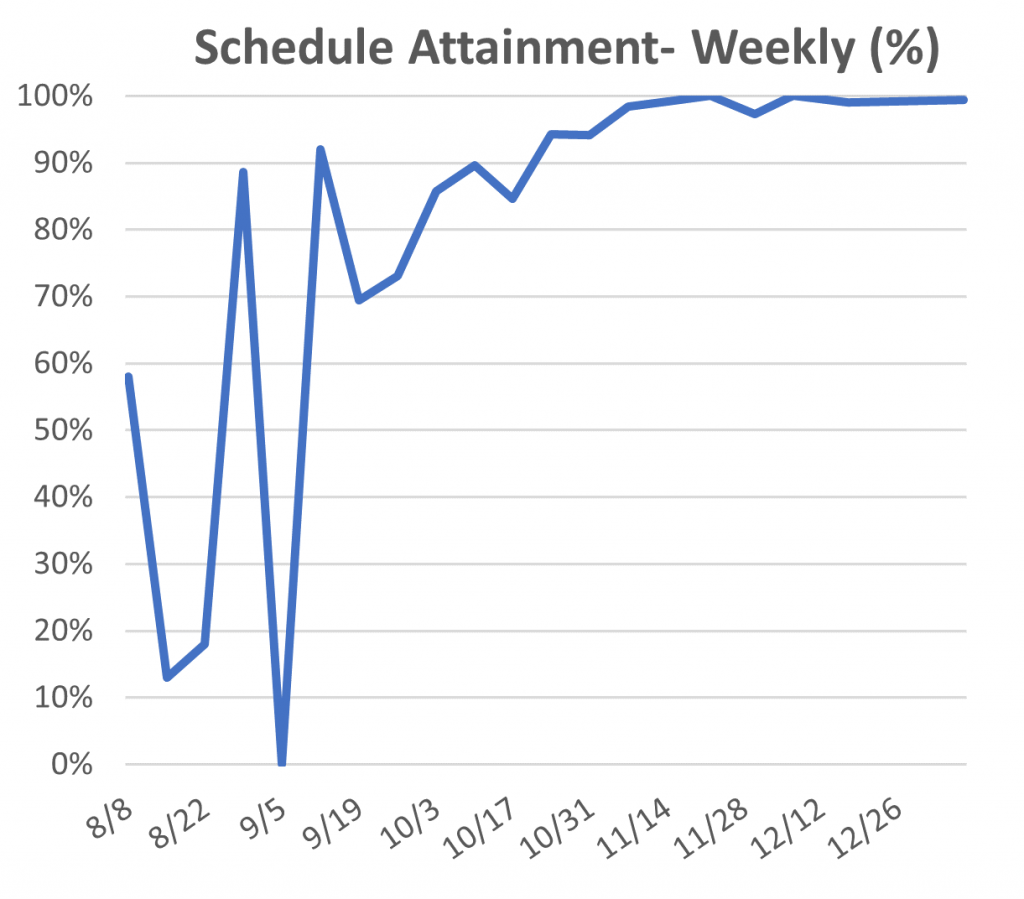

- Increased schedule attainment from 58% to 95% percent

Results:

- Reduced OT expenditures by 2.5% annually

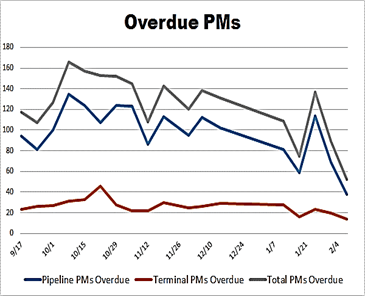

- Reduced overdue PMs (terminal and pipeline) by 31%

- Maintained miles driven while increasing headcount

- Reduced overdue maintenance