Background and Situation:

- Three site locations, each managing their own overhauls

- Coal/steam units ranging from 11MW – 100MW, Gas CT units < 50MW

- Overhauls were focused primarily on duration, limited emphasis on scope or budget

- Recent growth necessitated formal Outage/Capital Process

Objectives:

- Assess and develop project plan to improve the existing overhaul/capital management practices

- Lead action teams to establish formal documented outage/capital project management process

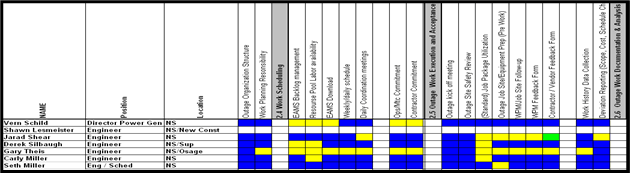

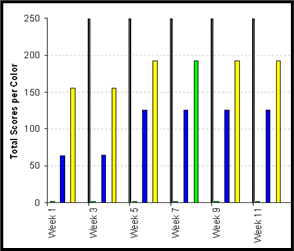

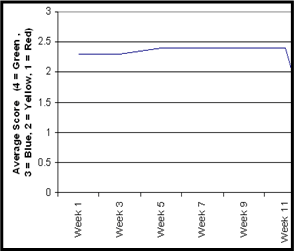

- Establish new organization focused on overhaul/capital project management and coach staff on the new desired processes

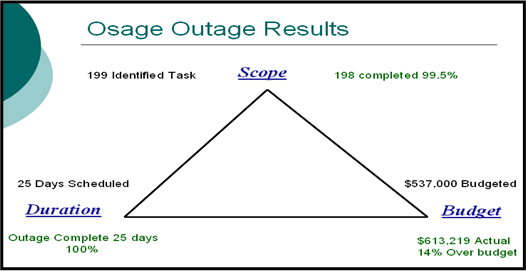

- Utilize new enhanced process to deliver successful spring outages

Results:

- Create and managed detailed project plan & roles/responsibilities to deliver project on schedule and under budget

- Due to proper work identification prior to the start of the BF overhaul. BHP was able to successfully complete the life extension project 2 years early with an estimated savings of $7.4 million

- 100% of staff trained at a level appropriate for their position

- Began to formalize process for the two smaller sites utilizing new process

- Field coached & coordinated staff activities to support training and implementation for the Outage/Project Management Process