Background:

- They had an excess of $100mm annual maintenance spend and 15% production downtime in 8 of their largest plants.

- Emergency break-in work was above 20%

- Inconsistent application of Computerized Maintenance Management System (CMMS)

- No standard enterprise-wide process or metrics in place to manage asset reliability or monitor process performance

- A mix of union and non-union facilities

- Operations was disconnected from equipment ownership

Objectives:

- Establish and implement common enterprise wide asset management process and practices

- Reduce emergency work to less than 10% by implementing a planned and scheduled corrective and PM/PDM program that focuses on critical equipment and critical manufacturing processes

- Establish meaningful enterprise wide plant level metrics that can be used to manage plant operations more proactively

- Increase production uptime

- Establish enterprise wide Asset Management Excellence leadership council to sustain results and maintain control of the standard enterprise wide process

- Build joint maintenance and operations ownership of equipment

- Reduce maintenance annual spend by 10% in 8 largest plants

Achievements:

- Delivered comprehensive comparative work management process assessment in each of the three major business groups

- Facilitated work process “best practices” design activity (Foundation Building)

- Improved overall maintenance productivity by 20% resulting in

- Reduced supplemental maintenance contractor cost by 75%

- Reduced operations and maintenance overtime by 60%

- Reduced headcount by 18%

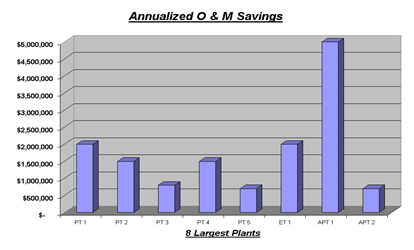

- Reduced maintenance cost in 8 largest plants by $14mm

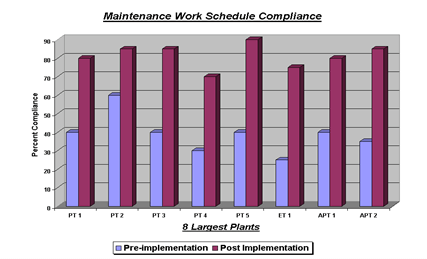

- Implemented standard daily and long-range scheduling processes at all locations, taking daily schedule compliance from < 40% to + 80%.

- Implemented a standard, prioritized planning process that resulted in 80% of scheduled jobs being planned.

- Implemented operator rounds and manufacturing instructions that improved the participation of operators in maintaining asset reliability (PM inspections, lubrication and operating standards)

- Implemented Sustainability Control Plan that included audit package, metrics collection and site level responsibilities